Dukes Moor Aerodrome

Location : North of Newcastle's Town Moor

OS Ref : NZ 240 668

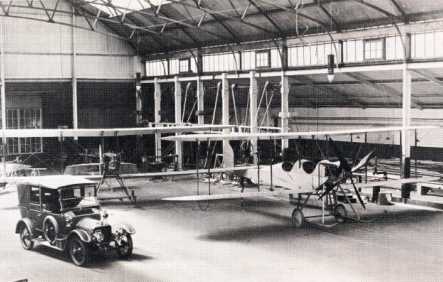

Armstrong-Whitworth established an aircraft manufacturing factory at Dukes Moor after launching an aircraft department in summer 1913 and receiving contracts to built aircraft under license from the war office. Initially two R.A.F. BE.2a machines (no's 383 and 385) from a batch of eight on order were built at the Scotswood works. Impressed with the build quality of the initial two aircraft, further RFC contracts were received for additional BE.2a, followed by BE.2b and later BE.2c machines all built on Dukes Moor.

The moor was a long, narrow strip measuring 600 x 150 yards. It was lined by both trees and houses but was chosen as a factory location nevertheless.

The factory was established in 1913 by taking over the building which had once served as the grandstand at the old Newcastle racecourse. The building at the western edge of the moor had been left behind when the town race meeting was moved from the Newcastle Town Moor to nearby Gosforth Park in 1882. Following the closure of the course, the building was taken over by the Roman Catholic authorities, and after carrying out extensive alterations was used as an Industrial school for boys (the Bishop Chadwick Memorial School). From 1910 to 1912 the premises served as a public skating rink.

The opening of the Gosforth Works in 1913 coincided with the arrival of a Chief Designer, a Dutchman called Frederick Koolhoven. Koolhoven immediately went to work carrying out a number of different experiments.

The Skating Rink which was to become an

Armstrong-Whitworth aircraft factory

(NEAM)

BE.2a's being built in the 'Skating Rink'

In early 1914, the Newcastle Evening Chronicle captured activity at the new factory by reporting the following in their 4th

February edition – “People

passing the large building near the Town Moor edge at Gosforth

formerly used as a skating rink have remarked on the activity going

on within the premises and have been curious to know the nature of

the industry for which the rink has afforded accommodation. As is

generally known, the building was secured by Messrs Armstrong,

Whitworth & Co a little while ago for the development of their

aeroplane business and now the interior of the place has a very busy

appearance. It is stated that the firm is, at the present time

building eight aeroplanes for the British Government”.

A.W FK.3 5528 outside the AW two-bay hangar on

Dukes Moor

(CCI)

Between November 1914 and March 1915 the site also was the home of 1Sqn RNAS C Flt / War Flight RNAS equipped with four Bristol TB.8s.

The AW FK.2 was an attempt by Koolhoven to build a biplane modelled on the BE.2c but simpler to manufacture. One, possibly two FK.2's were built and tested both at the Central Flying School in August 1915 and in France, but the RFC preferred the BE.2c which was already widely used. However, an order for a modified FK.2 was received, the result being the FK.3 with deliveries beginning in April 1916.

It is thought the FK.4 was the designation assigned to the cars that powered the Submarine Scout airships and based on the FK.3 fuselage. The FK.5 may have been a single engined triplane which never flew, but whose design influenced the FK.6, a triplane of similar design which had been ordered by the RFC, but cancelled after the first one was completed. In June 1916 a FK.3 was upgraded with a more powerful 120-hp Bearmore engine and it is thought that this inspired Koolhoven to build what is commonly referred to as the FK.7. A single FK.7 was built (A411) and this certainly was the forerunner to Armstrong Whitworth most successful design, the FK.8. The FK.8 was a two-seat Corps reconnaissance aircraft and though was in direct competition and more expensive than the R.A.F RE.8 was built in large numbers

The aerodromeremained in use until June 1916 when it was declared unsafe. Though the factory remained, a new aerodrome was established on the Newcastle town moor with Armstrong Whitworth bearing half the cost (approx. £600) and allowed them to transfer their flight testing to the new aerodrome.

Koolhoven's designs to date had been fairly conventional machines, but the FK.9 a two-seat Quadruplane delivered to the Central Flying School's test squadron in November 1916 was unique. Test results didn't make good reading, but the firm persevered with modifications which resulted in the FK.10. Due to the large scale production of the FK.8, the contract to build the FK.10 was given to another local Newcastle based firm, Angus Sanderson. A model showing a fifteen wing machine fitted to what appears to be a FK.10 fuselage was understood to be the FK.11 but it is doubtful that this ever got past the conceptual stage.

Koolhoven left Armstrong Whitworth during 1917, his place taken by F. Murphy who also acted as works manager. He designed two Scout aircraft - the Armadillo & Ara, the Armadillo was test flown from Cramlington, but proved unsatisfactory. The Ara though showing promise, the end of the war meant it was never going to be a contract forthcoming.

The Armstrong Whitworth Air Department closed in October 1919. A speech by the Lord Mayor of Newcastle claimed that the company had completed 1075 aeroplanes. It is known that 1047 machines were delivered by the end of 1918, in addition to 15 experimental machines. Yearly figures were 1914 (8 production + 1 experimental), 1915 (63 + 1), 1916 (124 + 2), 1917 (423 + 6) and 1918 (429 + 5). Those gave a weekly production of about 8 machines per week during the last two years of the war. In addition there were a further 200 partly completed machines and production did continue into 1919. Although Duke’s Moor remains an open space today, there is no evidence of the former factory.